This post is part 2 of a 2-part series on the importance of injector seals. If you’re just now discovering this post, be sure to tune in to part 1 before continuing here.

___________________________________________________________________

Like the title says, you need injector seals for your MZR! Here’s why.

When Mazda designs a part, they design it with the “typical” customer and OEM power in mind – not the power hungry, boost craving driver. Yeah, I’m talking about you and you know it – and we have just the thing to keep you and your MZR in check. As you add more fuel and more boost, the weakest link is eventually going to give. That link is the OEM injector seals.

Three Reasons You Need Injector Seals For Your Mazdaspeed

- Reliability is sacrificed using the OEM seals.

- Leaking seals causes loss of power.

- Inconsistent performance is caused by leaks.

So, if you are just tuning in to our blog, then shame on you, go read part one like everyone else! With that, let’s dive into the design of the seal and how it works.

We put 500 hard miles on the Speed3 and here are the results. 500 miles may not sound like a lot, but the company owned MS3 does not live the normal life. It spends most of its time on the dyno testing new products pull after pull, may have hit 35psi, and when it does hit the streets, it’s driven by an employee searching for the governor speed. I think we can all agree that the 500 miles was a fair amount of abuse to put the injector seals. Plus, other sets of seals have been running in alpha testers vehicles for thousands of miles without issue.

Now that we have that covered, let’s talk a bit more about the design of the seal and how it works.

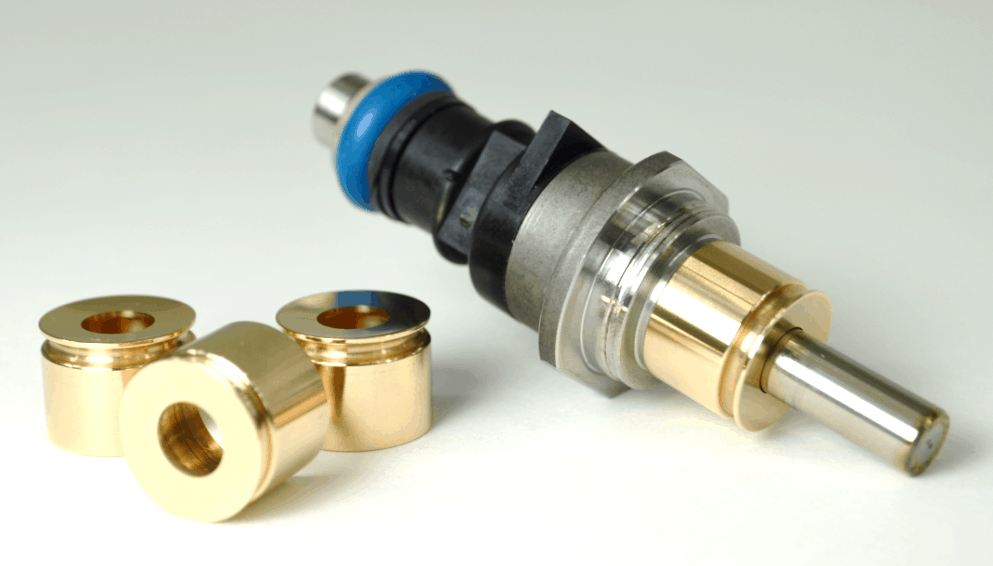

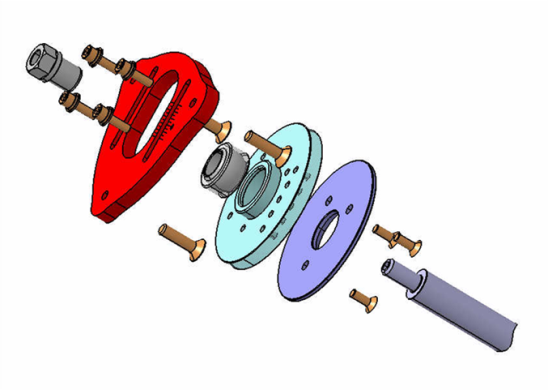

It’s no longer just a washer with one sealing surface – it’s a cup. So it seals in the OEM location AND along the side of the cup. The secret is in the design (which is all thanks to @Tokay444 from MazdaSpeedForums). The lip at the bottom of the cup is flared just a bit so that it crushes down tight against the cylinder head, and as it crushes down it also crushes outward, pushing against the wall of the port much like an O-ring. If you are having trouble visualizing the flared lip crushing outward then check out the image below. Time to get technical!

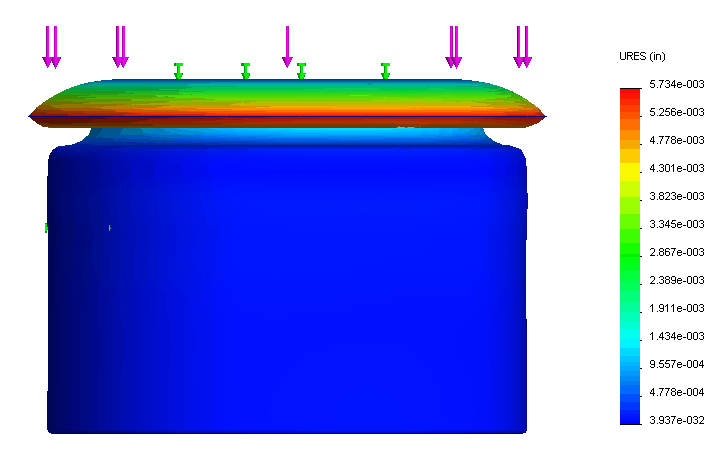

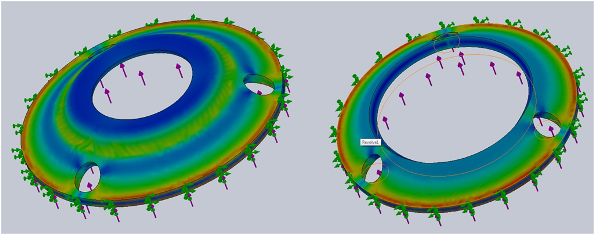

Looking at this side view of the seal, you can clearly see that the flared lip is extended further outward than the side of the seal. (Please note that in this FEA, or Finite Element Analysis, the deformation scale factor is 6.5:1, i.e. highly exaggerated). This design is what separates the CorkSport seal from any other seals on the market today. In the FEA the seal is subjected to 3300lbf in the direction of the arrows; 3300lbf is the approximate clamping force of an M8x1.25 torqued to 18ft-lb. The areas in red indicate a displacement of 0.0057 inches, which is just enough to begin yielding (permanently bending) the beryllium copper material. After the 500 miles of use, we had the four seals precision measured using a CMM (Coordinate Measuring Machine). On average, the seals yielded 0.0015 inches confirming our FEA.

Still following?

So what does this mean to you? When you torque down the fuel injector bolt and clamp you are applying approximately 3300lbf to the injector seal. This crushes the seal downward pushing the flared lip outward into the wall for ultimate sealing strength; and we have all the data to prove it! The CorkSport seal works flawlessly, but because of the design they are not reusable like any other crush seal.

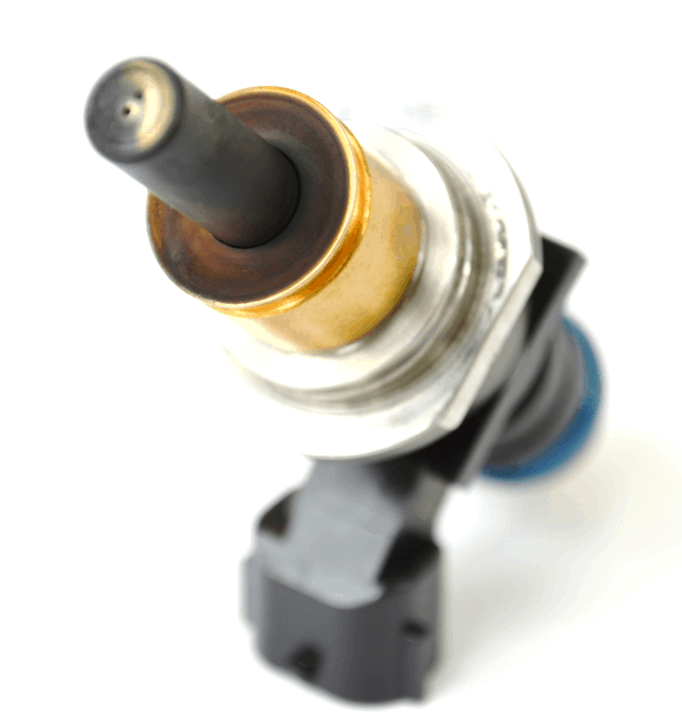

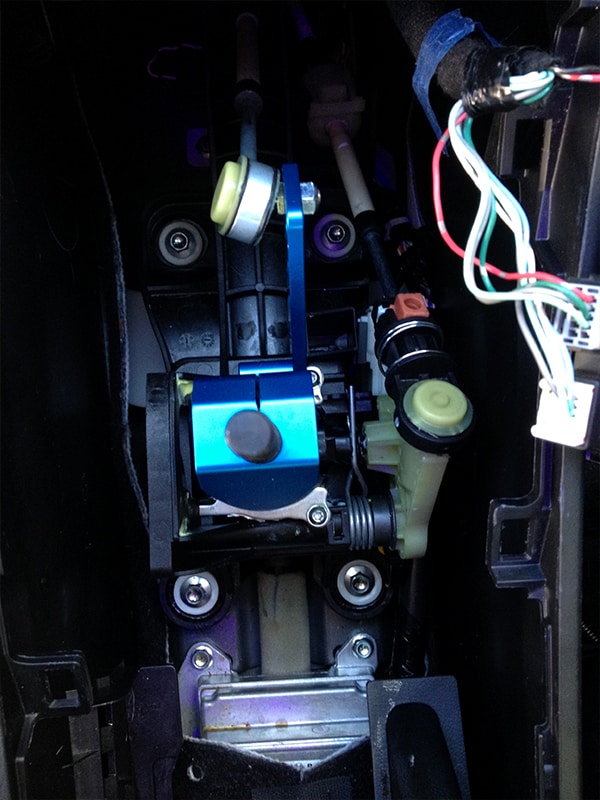

So, now that we are done with all the technical stuff let’s take a look at the used seals. First, I would like to remind you what the injector looked like with the OEM crush washer and only 4000 miles.

Extremely dirty with an excessive amount of combustion gases blowing by the OEM injector seal. This makes for a very unhappy MZR. Second, in the images you are about to see, the seals have not been cleaned in any way, shape, or form. I pulled these out of the car and immediately took the pictures. Prepare to be WOW’d; I know I was…

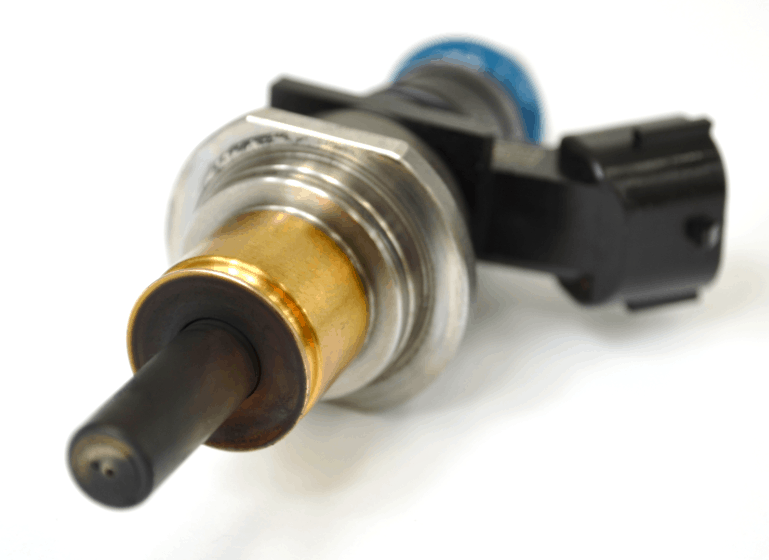

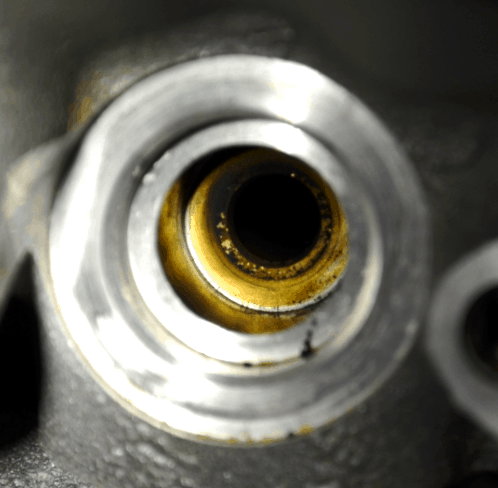

Besides the clean injector body, there is a more subtle detail that needs to be pointed out. If you look at the very edge of the flared lip on the seal you will notice that the black soot does not go all the way to the edge. This further confirms that the seals are working the way Brock (@Tokay444 on MSF) had envisioned them and we can also see this “clean ring” in the cylinder head below.

In the image below you will notice that the seal is dirty on the inside, but that’s okay – that happens by design. The “shelf” that you see midway up on the inside of the seal seals against the injector body instead of in the OEM location further down around the injector nozzle. This change in sealing location allows the flared edge to deflect how it needs.

If I haven’t convinced you yet why you need injector seals for your Speed3 then you’re hopeless…you should go get a Civic or something else that’s slow…

Between our results and the reviews given to us from our alpha testers we have great confidence in the seals and you should too! Keep an eye out for these to be released very soon! Zoom – Zoom! -Barett, CS Engineering